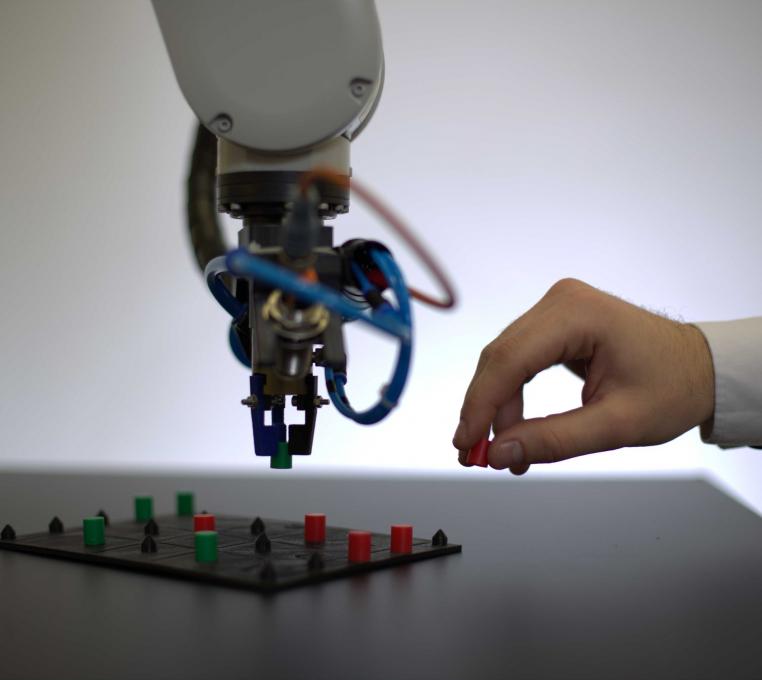

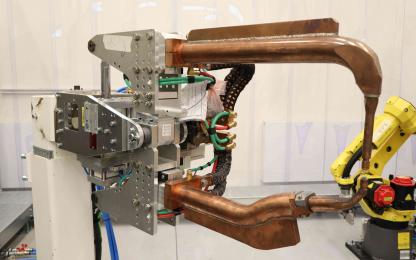

Caring both for the implementation stage as well as further development of our employees, we continue to expand and hone our test and training laboratory at the company seat. It is equipped, for instance, in KUKA, ABB and FANUC industrial robots, inverter stations, 3D printers as well as 3D measurement equipment.

We are currently working on starting up our robotised station being the component of a real production line. It is supposed to help our employees in starting work before setting off for on-line activity. The robotisation specialists have completed, set up and configured appropriately chosen devices that are necessary to start up the station. In order to recreate the reality of operation of a real industrial line, we also needed to build a complete safety system.